PTFE Compounds

PTFE Compounds

Learn all about properties and what Dechuang can do for your PTFE components.

Properties and Performance of PTFE Compounds

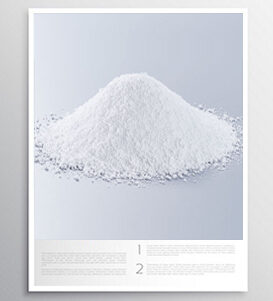

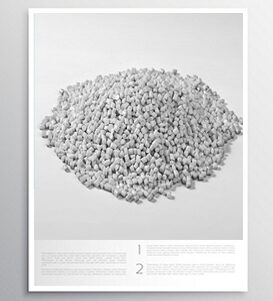

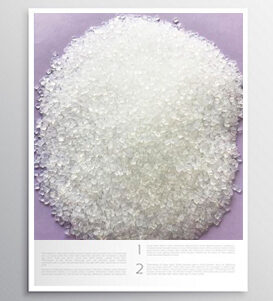

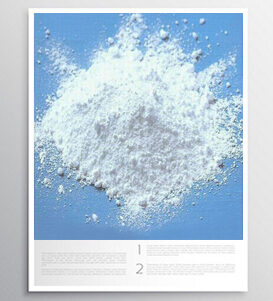

PTFE compounded with fillers like glass fibers, carbon, graphite, bronze, MoS2, PEEK etc. to improve physical, mechanical, thermal, wearing, electrical and chemical properties.

PTFE compounds and Functions that Benefit Your Parts

More special compounds, please contact our Experts.

Material Name | Compound % | Main Properties | Color |

Glass Fiber | Up to 40% | Improved ware resistance, compression strength, creep resistance, chemical resistance. Good performance in oxidising environment, good creep resistance. | White cream |

Carbon | Up to 35% | Improved electrical and termal conductivity, resistance to load, low coefficient of friction in dry, water, steam applications, chemical resistance. Superior ware resistance increase and low friction properties. | Black |

Graphite | Up to 25% | Improve wear resistance, decrease friction and increase sliding properties against soft metals- chemical inertness. Improve the temperature resistance in some way. | Black |

Bronze | Up to 60% | Improved compression strength, wear resistant, high thermal conductivity, resistance to abrasion. Reduced chemical resistance. | Dark Brown |

Molybdenum disulphide(MoS2) | up to 5% | Increased PTFE properties of hardness and wear resistance. Increased sliding properties and decrease friction. | Blue azure |

PEEK | Up to 20% | Increased thermal resistance, sliding properties, surface hardness. Superior properties on dynamic applications. | Beige |

Featured PTFE Compounds articles

Interested in More PTFE Samples?

Industrial

Customization

Custom Performance & Design

In house material compound capability and rich experience in PTFE filed can full fill your PTFE project.

Let’s Get in Touch

contact our team to receive the personalized offers about our products.

Custom Machining

We’ll review your volume & design, to determine a most cost-effective approach to your PTFE part production from our in house PTFE compression molding and PTFE machining.