PEEK – Polyetheretherketone

Learn all about properties and what Dechuang can do for your PEEK components.

Properties and Performance of PEEK

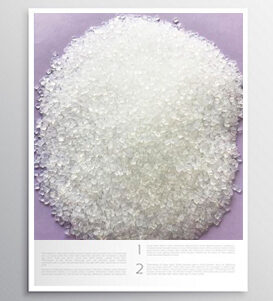

PEEK is a high-performance engineering plastic with outstanding chemical resistance, excellent mechanical strength and dimensional stabilization.

Enhanced Mechanical Properties with Filled Grades

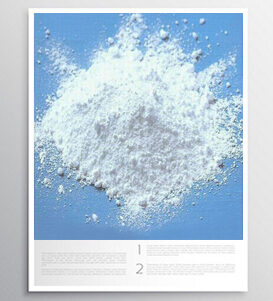

Standard PEEK virgin grade is suitable for laboratory and medical use. After being reinforced with glass fibers and carbon, its expansion rate is significantly reduced and the flexural module is increased. This makes it ideal for applications requiring increased stability, strength and rigidity at temperatures above 300°F.

Material Name | Compound % | Typical Application Areas | Color |

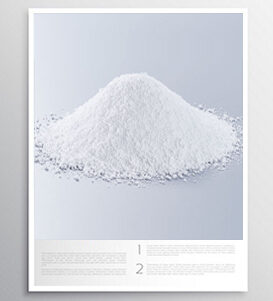

PEEK | / | High performance thermoplastic material, unreinforced PolyEtherEtherKetone (PEEK), semi crystalline, coarse powder for extrusion compounding, easy flow, FDA food contact compliant, colour natural. | Natural |

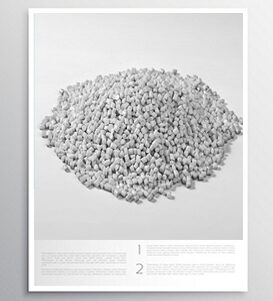

PEEK-450GL30 | PEEK with 30% Glass Fiber | Applications for higher strength in a static system. Low coefficient of thermal expansion. Chemically resistant to aggressive environments, suitable for sterilisation for medical and food contact applications. | Natural/Black |

PEEK-450CA30 | PEEK with 30% Carbon | Applications for higher strength and stiffness in a static or dynamic system. Excellent wear resistance, low coefficient of friction, low coefficient of thermal expansion. Chemically resistant to aggressive environments. | Black |

PEEK-450FC30 | PEEK + Carbon + Graphite + PTFE | Tribological applications for high strength. Excellent wear resistance, very low coefficient of friction, low coefficient of thermal expansion. Chemically resistant to aggressive environments. | Black |

Industrial

Customization

Custom Performance & Design

In house material compound capability and rich experience in PTFE filed can full fill your PTFE project.

Let’s Get in Touch

contact our team to receive the personalized offers about our products.

Custom Machining

We’ll review your volume & design, to determine a most cost-effective approach to your PTFE part production from our in house PTFE compression molding and PTFE machining.

Other Materials We Work With

Looking for another material of fluoropolymer? We have the ability to machine different materials in some of the other plastics which we work with.