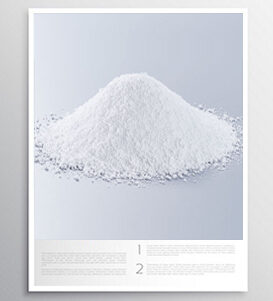

PTFE – Polytetrafluoroethylene

Learn all about properties and what Dechuang can do for your PTFE components.

Properties and Performance of PTFE

PTFE has a distinctive profile that makes it one of the most precious and flexible materials available for engineering.

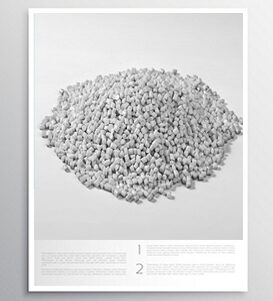

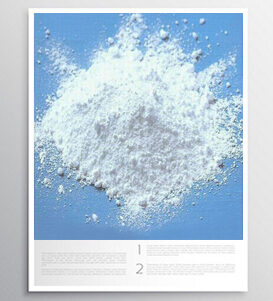

PTFE properties are often enhanced using a variety of fillers creating a PTFE compound, such as a 15 or 25% glass filled PTFE, to improve wear resistance, increase part stability, and improves creep strength and reduce deformation under load in comparison with virgin grade PTFE. PTFE resin does not flow when it melts and cannot be injection molded. The best method is molding and machining.

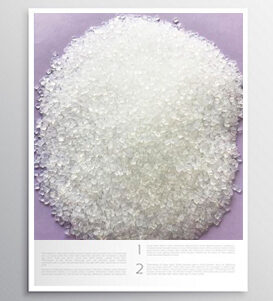

Modified PTFE

Modified PTFE is a chemically modified version of PTFE that has new capabilities in addition to the property characteristics consistent with virgin PTFE material.

Industrial

Customization

Custom Performance & Design

In house material compound capability and rich experience in PTFE filed can full fill your PTFE project.

Let’s Get in Touch

contact our team to receive the personalized offers about our products.

Custom Machining

We’ll review your volume & design, to determine a most cost-effective approach to your PTFE part production from our in house PTFE compression molding and PTFE machining.

Other Materials We Work With

Looking for another material of fluoropolymer? We have the ability to machine different materials in some of the other plastics which we work with.