Industries We Served

Thanks to the continuous research and study in fluoroplastic and the development of new

compounds, we have the ability to meet challenges from various industries.

Chemical

In the chemical industry, PTFE and PTFE compounds are widely used, giving parts excellent heat resistance and their chemical inertia. PTFE allow easy installation, minimize down time and ensure the highest reliability.

Food and Beverage

Dechuang provides plastic and rubber solutions for the most diverse applications in the food industry, including gastronomic workshops, distributors and major manufacturers of machinery. All products are FDA certified.

Aerospace

Dechuang can realize a vast quantity of plastic and rubber articles for the aerospace industry. The thermoplastic and elastomeric materials are ideal to meet the needs of this industry in terms of lightness, reliability, safety and durability.

Automotive

When exposed to high temperatures or aggressive fuels, fluoroplastics can maintain outstanding material properties. We offer popularly selected material for automotive applications with high reliability and cost efficiency.

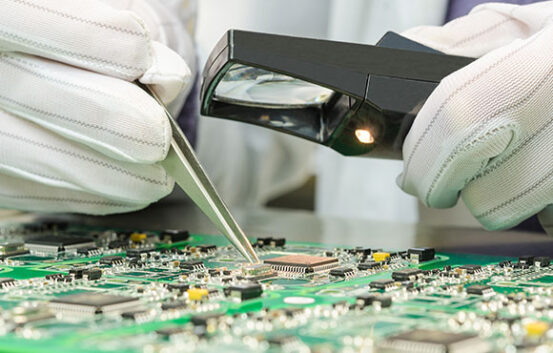

Electronics and Semiconductors

PTFE can be used in the manufacturing of semiconductors in a broad range of components. Specific properties include high purity, chemical resistance and excellent dimensional stabilization.

Mechanical Engineering

Improve efficiency, reduce weight and energy consumption. Our innovative PTFE and bonding technologies provide exceptional friction control performance and critical durability for Mechanical Engineering industry.

Oil and Gas

Parts for the oil & gas industry are high temperature and corrosion resistant, due to harsh chemicals such as hydrocarbons containing sulfur, superheated steam, carbon dioxide, methane and hydrogen sulfide.

pump valves

Dechuang Teflon products can design solutions for shaft seal products for demanding applications in industrial and manufacturing markets. Our shaft seal products can withstand super strong operating speed, pressure and temperature.