Custom Fluoropolymer Parts

Exacting precision. Unparalleled performance.

Custom Fabricated

Various processing techniques are ready to achieve your specifications. We will offer the best way to suit your part details, tolerances, quantities.

● Automatic Production

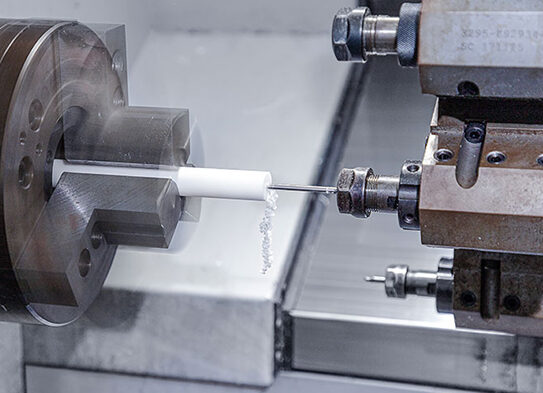

● CNC Lathe Machining

● CNC Machining

● Stamping

Custom Materials

Our technical knowledge and expertise in PTFE compounding also extend to other fluoropolymer materials.

● PTFE materials

● PEEK materials

● PVDF materials

● PCTFE materials

Stock Shapes

Regular Rods, tubes and sheets on stock to support the fast delivery and ultimate convenience.

● PTFE Tubes

● PTFE Rods

● PTFE Film

● PTFE Sheet

No Minimum Order

All of our products are available with no minimum order quantity, no hidden setup charges and fast lead times.

● Sufficient raw powder

● Sufficient profile

● Have many advanced machines

● Various processing methods

What Make Us Outstanding in Fluoropolymer Parts Custom

Combine that with the industry’s most accessible value-added services, Dechuang is chosen every day by device manufacturers around the world.

Inhouse Production

We keep every process internal and prioritized.

Ongoing R&D

Progress never stops ensuring consistent high quality.

Leading Technology

Industry pioneer technogies are seen in every process.

Meticulous Craftsmanship

No details are too small. We make each step count.

Fluoropolymer Parts Expert

Decades of experience makes us know more and deeper.

Mature Supply Chain

Long-term partners allow for our competitive resources.

Involved material and Standard Formulation PTFE compound

Need customized formulation? Just contact our engineering team for expert support.

Material Name | Compound % | Main Properties | Color |

PTFE | / | Very low coefficient of friction and excellent chemical resistance. FDA approved | White |

Glass Filled PTFE | Up to 40% | Improved ware resistance, compression strength, creep resistance, chemical resistance. Good performance in oxidising environment, good creep resistance. | White cream |

Carbon Filled PTFE | Up to 35% | Improved electrical and termal conductivity, resistance to load, low coefficient of friction in dry, water, steam applications, chemical resistance. Superior ware resistance increase and low friction properties. | Black |

Graphite Filled PTFE | Up to 25% | Improve wear resistance, decrease friction and increase sliding properties against soft metals- chemical inertness. Improve the temperature resistance in some way. | Black |

Bronze Filled PTFE | Up to 60% | Improved compression strength, wear resistant, high thermal conductivity, resistance to abrasion. Reduced chemical resistance. | Dark Brown |

Molybdenum disulphide(MoS2) Filled PTFE | up to 5% | Increased PTFE properties of hardness and wear resistance. Increased sliding properties and decrease friction. | Blue azure |

PEEK Filled PTFE | Up to 20% | Increased thermal resistance, sliding properties, surface hardness. Superior properties on dynamic applications. | Beige |

PEEK | / | Excellent mechanical properties including strength, rigidity, impact resistance, low wear rate and low coefficient of friction, retained over a wide range of service temperatures | Light Brown |

PEEK compound | / | Improves technical and chemical properties like deformation under load, wear resistance, thermal expansion and electrical conductivity. | / |

PVDF | / | Resistant to UV radiation and offers high mechanical strength and abrasion resistance. | Beige |

PCTFE | / | Better mechanical properties than other fluoropolymers, low permeability | Translucent |

PFA | / | Excellent chemical and temperature resistance, electrical insulation and excellent processability | Natural |

More Than Just Parts Machining Services

Professional Machining Advice

Dechuang can offer suggestions to keep costs down while you are designing precision, high-quality components of PTFE and other fluoropolymer materials.During our quoting process and review of your specs, we will propose the best way to produce the components and make suggestions if we feel a part feature or tolerance needs adjusting to best suit PTFE.

- Prediction of fillers effect

- Technical material characteristics

- Parts manufacturability

Third-party Inspection Support

For parts we manufacture in our factory, we provide materials in-house test reports and material characteristics reports. For finished parts requiring third-party inspection, we’ve also got you covered.

Our third-party inspections help minimize the risk of defective products by ensuring they meet both your standards and industry and government regulations.

Traceability of Each Batch

Complete identification and documentation from the receipt of goods, weighing, and mixing of all raw materials up to filling, molding and order execution of the final product: